Featured Coolants

25 YRS

The Industry leader in U.S. Patents for Waterless Engine Coolants Trusted for Over

WATERLESS COOLANT BENEFITS

Evans waterless coolants offer several benefits to save you money, time and engine wear.

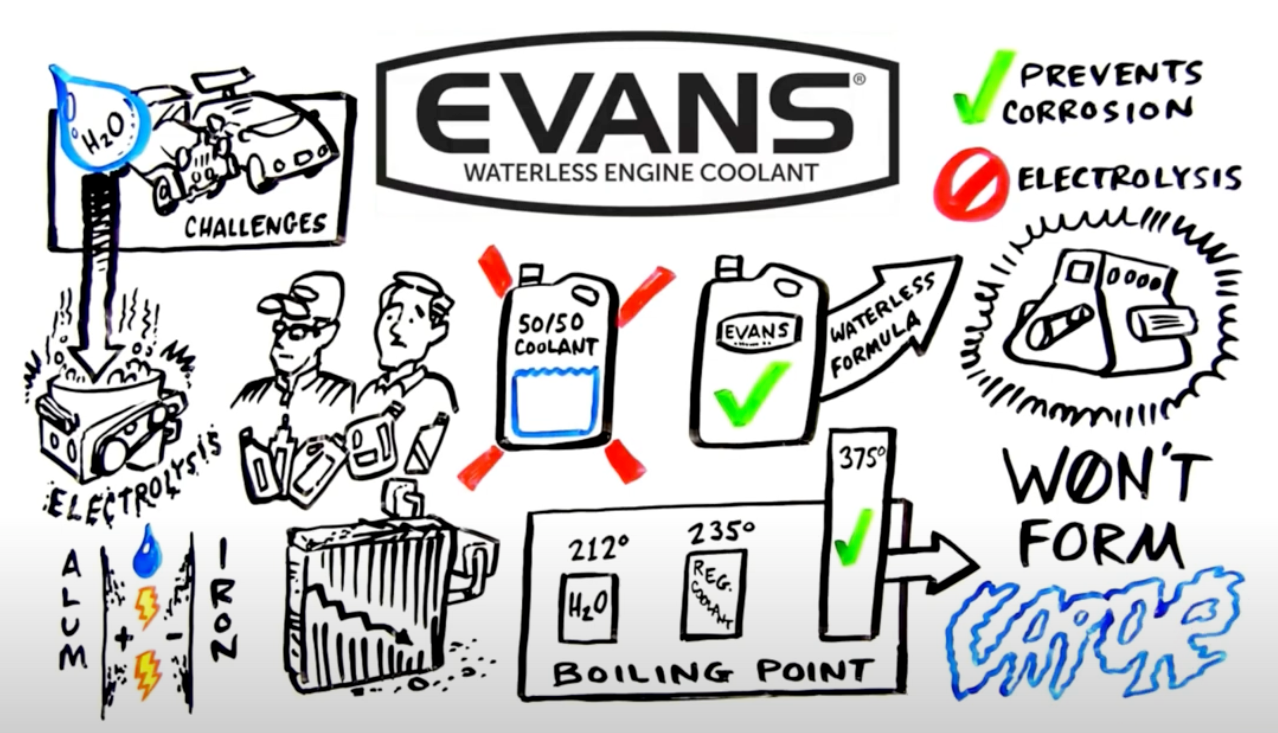

Evans Waterless Coolant provides distinct advantages over traditional water-based coolant. The absence of water avoids the formation of vapor, high pressure and boil-over, and prevents corrosion and electrolysis. Evans’ high boiling point and lower freeze point allow a wider and safer operating temperature range. The benefits derived from Evans can be achieved in most vehicle applications and engine types, although Evans’ performance may vary depending on cooling system configurations.

No Corrosion

By removing water from the cooling components, Evans eliminates water-caused corrosion in the cooling system.

No Pressure

Evans coolants will always remain in liquid form, preventing stress on cooling system components such as hoses, pump seals and radiator seams due to high vapor pressure.

No Overheating

With a boiling point of 375ºF compared to only 226ºF for water-based antifreeze, Evans Waterless Coolants expand the range of safe operating temperatures in you vehicle while eliminating the risk of boil over.

No Erosion

Even under extreme conditions, Evans coolants remain in liquid form and do not vaporize, preventing the pitting caused by water vapor.

No Electrolysis

The absence of water, substantially reduces electrical conductivity of Evans coolants which sharply reduces incidents of electrolysis.

Freeze Protection

Evans coolants have natural antifreeze properties down to -40°F and will not solidify or expand, providing protection from freeze bursts.

Extended Lifecycle

Evans coolants do not degrade and are designed to provide an extended service, in many cases resulting in a lifetime fill.

PROTECT YOUR INVESTMENT

Evans coolant eliminates many problems associated with water in conventional water-based cooling systems, while preserving the engine for a lifetime.

About Waterless Coolant

Traditional engine coolant is 50% water, but water causes engine corrosion and overheating. Evans Waterless Coolant is a glycol-based fluid that contains no water, so it eliminates many of the problems of water-based cooling systems.

WHAT IS WATERLESS COOLANT?

- Water has superior heat transfer capabilities but water’s low boiling point is close to the operating temperature of an engine, and water can cause corrosion.

- Waterless coolants provide sufficient heat transfer, boil at a higher temperature, and are non-corrosive.

WHY EVANS

- Evans is the only manufacturer of waterless antifreeze.

- Installing Evans waterless coolant eliminates many problems associated with water in conventional water-based cooling systems, while increasing reliability and engine life.

AUTO CLASSIC & VINTAGE COOLANT

Evans Collectors Choice waterless coolant is designed to preserve vintage and classic gasoline vehicles, and light duty diesel engines.

HIGH PERFORMANCE COOLANT

Evans High Performance Waterless Coolant is designed for all gasoline and light duty diesel engines. Evans coolant eliminates many problems associated with water in conventional water-based cooling systems, while increasing reliability and engine life. You love your vehicle—it deserves Evans. The wilderness is no place for overheating. Keep your off-roading on track with Evans

4x4 OVERLAND

MUSCLE CAR

So far we like the Evans Coolant it keeps the temp pretty stable cools down fast after a run.

Can’t believe how much cooler the car runs with your product & cuts cool down time in half. Great job guys !!!

I love Evans because it doesn’t form vapor pressure!

We couldn’t have achieved this win and our continued success both on and off the track in 2018 without Evans!"

"With Evans coolant I notice my engine doesn't run as hot and it's easier to cool it down between rounds. As a bonus, it doesn't corrode my aluminum block, heads and radiator like other coolants or plain water have".

A REVOLUTION IN COOLANT

For decades, engine designers and antifreeze formulators have tried to overcome the intrinsic shortcomings of water because there has been no viable alternative. Now there is.

Evans manufactures the ONLY line of waterless engine coolants. Evans coolants do not use water, and therefore eliminate the engine problems caused by water.